- CUSTOM SERVICES

China Aluminum Casting Factory – Gravity, Low Pressure & High Pressure Die Casting

Custom Made from Drawings or Samples

Mold design+Casting+Blasting+Machining+Leak test+CMM test+X-ray test

- ABOUT DETAIL

CUSTOM ALUMINUM CASTING factory.

The best custom aluminum casting manufacturers takes your ideas from drawings to products.

Detail custom services

- Custom Aluminum Castings

- Self-owned Factory

- Free Maintenance Of Mold

01.

aUTO PARTS

Charge air cooler tanks, turbo housing, Manifold and so on.

02.

Decoration industry

Decorative Bollard, decorative base, Light base and so on.

03.

Textile industry

Weaving beam flange and other parts.

04.

CUSTOM-MADE SERVICE

Takes your idears from drawings to Products.

05.

Electricity industry

Junction housing and other parts.

06.

Gas industry

Valve housing, Pump housing

Custom Aluminum castings

The best custom aluminum casting manufacturers takes your ideas from drawings to Products.

Self-Owned Factory

We make custom castings in-house to cut costs and ensure quality products are delivered faster.

Free maintenance of molds

We provide free, Maintenance for our molds to ensure their durability and optimal performance.

Our Main product

Product Classification

CAC Tanks

If you are in the OE market, send me the drawings for a quote.

If you are in the aftermarket, send a product image for stock availability.

Decorate Base

Custom-made decoratove bases in various shapes.

If you have drawings, You can send to me.

Weaving Beam Flange

Custom-made all size of weaving beams flange.

Feel free to share your designs with us for product customization。

Aluminum Valve Housing

100% Leak test

Many companies are using aluminum for lighter valves housing.

How can I determine which process is suitable for my aluminum products?

22+ years of experience in aluminum casting

Customized your aluminum products

Why choose us?

1. Help you convert drawings to products.

2. 100% leak test before shipping

3. Passed the 16949 quality system certification

OEM / IATF 16949

About XD

With 22 years in the aluminum gravity casting industry, our company boasts extensive experience and a robust team of 3 process improvement experts, 17 inspectors and engineers, and over 200 skilled workers. This enables us to meet large-scale production needs and deliver on time.

Process Flow Diagrams

XD melting aluminum in a furnace until it reaches the necessary fluidity, then pouring it into molds using gravity casting to achieve precise and detailed shapes. This process is essential for producing high-quality customized aluminum castings.

XD inspecting and repairing the cast aluminum blanks to remove any excess material or imperfections, followed by machining the prepared blanks to achieve the precise dimensions and surface quality required for the final product.

XD is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but al

XD uses ultrasonic waves to deeply clean the aluminum castings, effectively removing contaminants such as oils and residues. This ensures the castings are thoroughly clean for further processing or final use.

XD customizing the packaging of aluminum castings based on specific customer specifications to ensure safe transport and delivery. This stage is crucial for protecting the quality of the products during transit and for meeting diverse logistical needs.

Our Workshop

FACTORY OUTSIDE

FROUNT OF FACTORY

Activity Room

Conference Room

X-ray Inspection

Coordinate Measuring

Mold Area

Inventory

Circulation Area

Raw Material Area

Machining Area

Machining Area 2

Machining Area 3

Newly Produced

Shipping

Quality Assurance

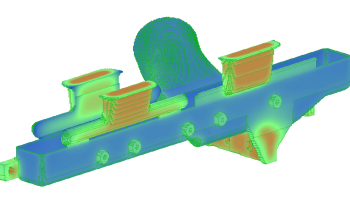

Mold Flow Analysis

Optimize mold design, prevent casting defects, and improve product structure.

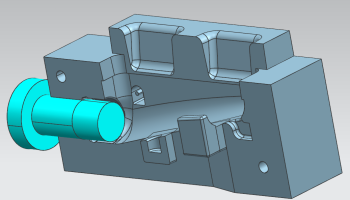

Mold Design

Runner and riser system setup, exhaust system improvement, casting method, extensive experience.

X-ray Inspection

Detect internal defects in products, ensure product quality.

Tensile Testing Machine

Mechanical property testing through specimens (yield strength, tensile strength).

Coordinate Measuring Machine (CMM)

Spatial dimension, geometric tolerance inspection, precise measurement.

Advanced Four-Axis CNC Machining Center

One-time clamping, ensures product precision.

Spectrometer

Elemental content analysis, detection of silicon, magnesium, and other elements, impurity analysis.

Cleanliness Tester

Detects surface cleanliness of products, analyzes impurity particles and weight.

Hydrogen Measurement Instrument

Detects aluminum melt density, analyzes hydrogen content in aluminum melt, ensures product quality.

Customize Your Aluminum Castings

Customize your aluminum castings with ease. You can send us your drawings or samples for customization, And we can recommend the most suitable production process based on the structure of your product. Whether you have precise specifications or need expert guidance on the best manufacturing approach, we are here to tailor our services to meet your unique needs